What respiratory protective equipment should be used for licensed asbestos removal?

When asbestos is disturbed or damaged, it releases toxic fibres into the air. When a person ingests those fibres, they can adhere to the lungs and be impossible to detect or remove. Over time, life-threatening diseases can develop, including different types of cancer.

While some asbestos-containing materials (ACMs) may be presently undamaged, renovation work and other projects have the potential to disturb ACMs. Also, damaged ACMs often require removal so that a building is safe for occupants.

Respiratory protective equipment (RPE) is a type of personal protective equipment (PPE) that ensures workers breathe in safe, clean air instead of hazardous substances. According to the Control of Asbestos Regulations 2012 and the Health and Safety Executive (HSE), employers are required to provide workers with PPE if there’s a risk of asbestos exposure.

What types of respiratory protective equipment are used for asbestos removal?

Any RPE that’s worn during asbestos work must have a minimum assigned protection factor (APF) of 20. Examples of RPE are:

- Disposable respirator: EN 149 (type FFP3) or EN 1827 (type FMP3)

- Half-mask respirator: EN 140 with a P3 filter

- Semi-disposable respirator: EN 405 with a P3 filter

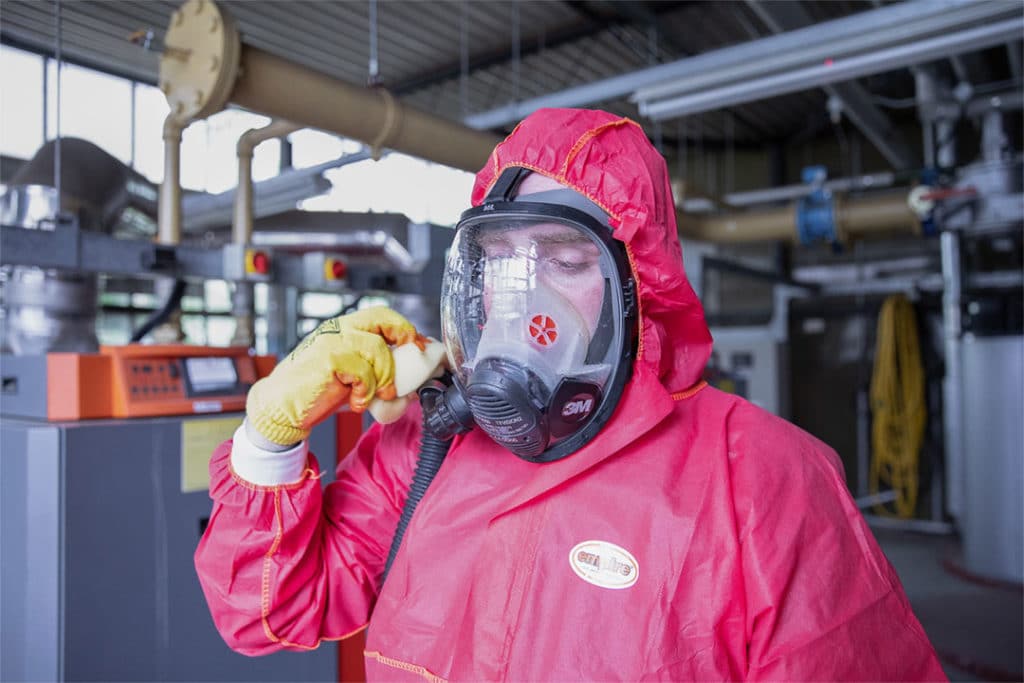

In live enclosures with a higher risk, full-face respirators with an APR of 40 and fitted with a P3 filter are worn.

- BS EN 136 full-face mask with BS EN 143 filter

- Power-assisted TM3 full-face mask (BS EN 147 or BS EN 12942) with P3 filter

- Fresh-air hose BA BS EN 138/269

- Constant-flow compressed airline BA hood BS EN 270/271 and mask BS EN 139

If disposable respirators are used, they should be disposed of in the same manner as asbestos waste.

Half-face vs. full-face respirators

The most important difference between half-face and full-face respirators is how much protection they offer. Half-mask respirators, whether they’re disposable or non-disposable, offer a protection factor of 20. Full-face respirators offer a protection factor of 40.

There are also differences in fit testing. Qualitative fit testing is sometimes used for half-face RPE. Odour and/or tasting compounds are used, and the wearer determines if they can identify leakage.

Quantitative fit testing, on the other hand, is always used for full-face RPE. Specialty equipment, specifically a porta count machine, accurately measures RPE leakage by counting how many particles have made it into the RPE.

Powered air-purifying respirators

Powered air-purifying respirators (PAPRs) have a helmet, a hood, and a powered pump. The pump pulls in air, which is then filtered and sent through the helmet’s vent. The helmet is then filled with clean air that goes out through the bottom of the helmet’s neck hole. This ensures that only safe, filtered air gets into the helmet for the wearer to breathe.

How do you select the respirator to wear for the job?

Deciding which RPE to wear depends on the scope of the work and if licensing is required.

For low-risk asbestos remediation, including non-licensed work and minor licensed jobs, half-face RPE with an APF of 20 may be suitable. These respirators offer an acceptable level of protection against low to moderate levels of fibre concentration.

For higher-risk asbestos work, including licensed projects within enclosures, RPE with an APF of 40 is often necessary for more protection. Full-face, positive-pressure respirators offer full coverage to protect the worker’s respiratory system, eyes, and face from asbestos exposure.

When work takes place within an enclosure, there’s a higher risk of asbestos exposure because the enclosed space can increase the concentration of fibres in the air. To protect workers, more comprehensive RPE is needed.

How do filters work in respiratory protective equipment?

The APF of RPE for asbestos work should never be below 20. According to the HSE, the RPE should have an APF that’s higher than the calculated necessary value. This is the best way to ensure the most protection possible.

Respirators filter out hazardous substances so the worker only breathes in clean, safe air. However, RPE only works if it fits the wearer correctly. Face-fit testing is used to determine whether or not RPE fits the person wearing it.

During face-fit testing, professional testers, asbestos workers, or both determine if particles are getting inside the mask. If particles are found to be leaking into the mask, that means the equipment isn’t sealing properly.

Testing methods range from using particles with an odour so the wearer can smell if they’ve leaked in to using high-tech equipment that counts the particles in the respirator. Also, the wearer will be asked to move around the same way they’re expected to on the job site for a real-world experience.

What factors influence the choice of respiratory equipment?

The type of RPE selected has to be the right match for the asbestos work that’s planned. Selection criteria takes into account the following:

- Concentration of asbestos in the air

- Duration of exposure and how long RPE will need to be worn

- Other hazardous substances (gas, for example)

- Type of work (for example, strenuous work requires more air)

- Communication needs while the RPE is being worn

- Work conditions, including the temperature

- User comfort and specifications, including facial characteristics and the person’s health

Whatever RPE is chosen, it’s critical that it fits the user well and creates a seal that prevents asbestos fibres from getting in. It should also be relatively comfortable to wear, and it shouldn’t add any extra hazards that could put the worker in danger.

How should respiratory protective equipment be used correctly?

In addition to selecting the right RPE and ensuring it fits well, donning and doffing procedures as well as breathing strategies are important to know.

Donning and doffing

Donning and doffing — or putting on and taking off — RPE has to follow specific protocols to be safe and effective:

- Donning and doffing should always take place outside of the work area but close to it, in a clean decontamination area.

- All jewellery, accessories, and anything that could get in the way of RPE or PPE should be removed before donning.

- PPE needs to be put on in the correct order so that the wearer is adequately protected. Typically, that means putting on boots and overalls first, followed by the respirator, additional eye or face protection (if needed), gloves, and the hood.

Remember, contaminated PPE and RPE has to be cleaned or disposed of the same way as other equipment and waste.

Breathing techniques when wearing RPE

Since RPE is designed to provide the wearer with clean air, there shouldn’t be any substances the wearer inhales that irritate them. Also, RPE doesn’t physically limit breathing. Still, it can feel awkward to breathe using RPE, especially for those who aren’t used to it.

Once a fit test has confirmed that the RPE is reasonably comfortable for the wearer, any feelings of discomfort will typically stem from the person’s breathing patterns. That can be impacted if the wearer feels anxious about wearing the equipment.

To smooth out breathing in order to not breathe too fast or too slow, which can lead to dizziness or shortness of breath, deep breathing and breath-regulation techniques, like box breathing, can be used. Belly breathing is also helpful for people who feel tense while wearing RPE.

How is respiratory protective equipment maintained?

Before it can be worn, RPE must be checked to ensure it’s in good condition. Maintenance checks include assessing the condition of the following:

- Head harness, facepiece, seal, and visor

- Inhalation and exhalation valves

- Threaded connectors and seals

- Filters, including expiry dates

- Battery packs, including checking their charges

- Airflow rate of power-assisted RPE

Additionally, RPE should be complete, meaning all of the components are accounted for, and it should be assembled properly before the wearer puts it on.

On top of checking the condition of RPE before putting it, a more thorough monthly test is necessary. Records of these examinations must be retained for five years, and the checks should be carried out by a person with training in the field.

What training teaches the effective use of RPE in asbestos removal?

The United Kingdom Asbestos Training Association (UKATA) offers an RPE Competent Person training course for supervisors and others who will be checking RPE on a monthly basis to ensure their employees’ safety. UKATA also has a Licensable Work With Asbestos course that caters to anyone who will be performing licensable work with ACMs. Training modules for this course include information about PPE and RPE. UKATA is considered the UK’s leading association for asbestos training, and it regularly audits members to ensure all training provided is compliant.

Conclusion: Ensuring safety through proper respiratory protection

Working with any type of asbestos poses a high risk, and there’s no such thing as a safe asbestos exposure event. RPE and other types of PPE help prevent workers from inhaling or ingesting dangerous asbestos fibres. When used along with other control methods, a worker’s risk can be reduced as much as possible.

If you need help with asbestos compliance, selecting RPE, or RPE fit-testing, contact Oracle today.

Written by Brendan Coleman

Brendan Coleman, with decades of experience in the asbestos industry, is a dedicated Quality Manager. Certified as a surveyor and analyst, he is adept in operations and quality management with a keen focus on HSE compliance. His expertise is pivotal in maintaining high safety and efficiency standards. Brendan ensures our UKAS accreditation requirements are consistently met and exceeded, upholding stringent standards in asbestos remediation. His commitment to enhancing quality and customer satisfaction makes him an essential advisor in asbestos management.